|

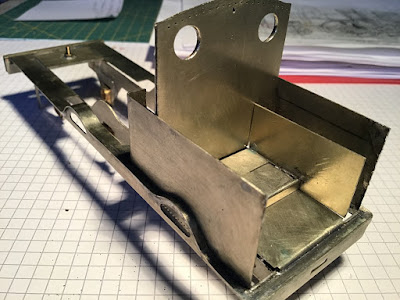

| HR56 Brake cylinder and associated mechanism. |

It often takes longer to work out what you're looking at and how to make it than to actually do the job and the brake mechanism of HR56 is an example of this. The brake cylinders and the link to the transverse brake shaft, which can be seen just behind the rear wheel, are the same on both sides, however on the right of the engine only, just in front of the brake cylinder there is what seems to be a tap, possibly for drainage of the system. The detail here was derived from photos and from Charlie Wrigley's article on the braking systems of the Stroudley Tanks in HRJ 107. It's all a bit of a tight fit leaving no room at all for a rear sanding mechanism.

|

| Brake mechanism, coupling rods and brake pull-rods on display. |

Inside the cab, directly above the brake cylinder on this side, is the brake standard. A threaded operating rod can be seen between the brake cylinder and the drain tap which is connected to the transverse shaft inside the frames by an operating arm.

The rods connecting the brakes across the engine are made from 1.2 mm tube. The brake pull rods are screwed into the tub with 16BA cheese heads and can be removed. A spot of solder in the tube ends, which is then drilled and tapped, secures the screws.

Coupling rods are jointed and made by Premier Components, however they had a flat profile and had to be shaped between the bosses to improve their looks, a job that necessitated the purchase of some new files as the metal of these rods is hard.

|

| ABCGears Mini 7S with M1824 motor in place. |

The brake pull rods are bent both outwards and down slightly to allow clearance for the coupling rod bosses. I cut these from 0.4 nickle silver sheet, making a crenelated shape in the flat which allowed for the downward aspect of the rods. All bends were then made in the vertical plane and the holes drilled afterwards.

The motor and gearbox as fitted does not leave room for a flywheel inside the superstructure, it is in fact the wrong mechanism for this engine so is due to be replaced with an ABC Mini Gooch with the same M1824 motor which will allow for a flywheel which will maximise the engine's running qualities.

A glimpse of the inside workings is afforded by the cut-out behind the front driving wheels. I did not model the inside motion fully, however I did solder representations of the connecting rods in place between the frames to give some impression of the works within.

|

| HR56 Cab interior. |

The brake standard can be seen on the right of the cab. The coal hole door is open and real coal will be added later to the Milliput base. The rivets on the boiler fairing are from Archer Surface Detail, these are resin transfer rivets, they are the largest I could find and have been used above and below the cab windows too. Though prominent at this stage, when painted they will be mere pimples which is probably appropriate at least for those round the windows.

|

| Milliput base in bunker to which real coal will be added. The Highland Railway added the bunker c.1910. |

|

| Smokebox and buffer beam detail. |

The route that the vacuum pipe follows perplexed me somewhat as it is not apparent on photos of the engine and vacuum pipes do not appear on the Ward drawing of no.57 to which they were never fitted. After a good deal of thought I decided that the pipe must run along the underside of the buffer beam, then go up to footplate level and run inside the vallance on the right of the engine.

The buffer beam is a sandwich of nickle silver outers with a Milliput filling to simulate the wooden beam of the original. The sprung buffers are from Walsall Model Industries, the buffer housings were detailed by the addition of hex bolts supplied by Prime Miniatures.

|

| Laurie Griffin supplied the HR lamps to which I added the brilliants. |

|

| The wide cab opening allows a good view of the cab interior detail. |

The rear coal bunker was added to HR56 around 1910 and at the same time the lamp irons on the rear buffer beam seem to have disappeared. The rear windows were rather longer before this time too and seem to have been made smaller in response to the addition of the bunker.

|

| Vacuum pipes and wheels with diametrically opposed holes on all drivers are an identifying feature of this engine. The gap between side tanks and cab forward extension is another characteristic feature of HR56. |

When the HR revised the braking system of HR56 (1896?) a front brake was added. As built the engine had brakes only on the centre and rear wheels so the change involved moving the guard irons forward to make room. I discovered this when I came to fit the brakes to my model. I originally positioned the guard irons from the Ward drawing, which shows HR57 as built, so when I came to fit the brakes I had to move the guard irons forward; photographs of the engine confirm the new forward position of the guard irons.

The completed engine, with a little weight in the side tanks and ash pan, weighs in at 600g. Her pulling power should match that of the real engine though a run on the CDOGG club layout in Carlisle should clarify this.

My aim in scratch building this little engine has been to build the best model I can with no concern for time taken nor for that matter the cost. I hope it might even be the best model of the engine yet built, I just don't know...and anyway I doubt whether many HR56's have ever been built in 7mm scale. As to the cost... a conservative estimate would be an outlay of £400. On the credit side the project has afforded me many hours of involvement, amusement and pleasure, though tempered with moments of anguish, frustration and despair. And... I've learned a lot. It all adds up to the conclusion that £400 is a mere trifle.